2019年10月11日に開催した専門性を生かすキャリアパスセミナー「市場を創り出す~未踏の領域でのソフトウェア開発~」の講師にお招きした石井恵三(株式会社くいんと 代表取締役)さんに、数学を専攻している学生と教員に向けて専門性を生かした企業の現場についてお話をしていただきました。

日時: 2019年10月11日(金)16:30~18:30

場所: 理学部3号館2階 第3講義室(3-205)

講師: 石井 惠三 氏(株式会社くいんと 代表取締役)

主催: 北海道大学大学院理学研究院数学部門

共催:北海道大学物質科学フロンティアを開拓するAmbitiousリーダー育成プログラム/博士人材の未来を拓く北海道大学理工系大学院教育改革Ph.Discover/北海道大学大学院理学研究院/北海道大学大学院理学院

(1)のつづき

バイクのパーツ軽量化で採算クリア

1989年にトポロジー最適化の商用ソフトウェアOPTISHAPE(オプティシェイプ)を作り、日本中のいろいろな会社に魅力を説明して回りました。手厳しいことを言われて落ち込むこともありましたが、1500年代の戦国時代に布教に来た宣教師フランシスコ・ザビエルの心境で、「諦めてはいけない」と気持ちを奮い立たせて、次の会社に向かいました。

そしてたどり着いたのが栃木にある、名前は申し上げませんが、かつて1980年代の終わりにアイルトン・セナとアラン・プロストという天才ドライバーを2人を擁しF1レースを席巻していた日本の自動車メーカー。そちらの方が「役に立つかどうかわからないけれど、とにかく面白い!」と買ってくれたのです。初めての成約でした。

ただひとつ心配だったことはOPTISHAPEがそれなりの価格でしたので、買うという決断をした方が責任を問われてクビになっていないかと。それが怖くてなかなか連絡できなかったのですが、半年後におそるおそる電話をしてみると、「あー、あの件は既にペイしたので心配ないですよー」と明るく言ってくださって、半年間の悶々とした思いがすっと消えて、思わず嬉し涙が出ました。

ではその自動車会社は何をしたのかというと、そこは二輪の分野でも世界トップクラスで、二輪にはライダーが足を置くステップと後ろに乗る人が足を置くステップの間に、当時は「雲型定規」のようなアルミ製の部品があるんですね。ぽこぽこと穴が空いている形状です。

それをOPTISHAPEでトポロジー最適化を試みた結果、穴のパターンが変わり、パーツの剛性を確保しつつ27%の軽量化に成功しました。アルミは鉄の4、5倍値段が高く、軽量化できたパーツを100万個生産して浮いた材料費だけでソフトウェアの購入費はすぐに消化できたと言われました。「やっぱり頭のいい人はすぐに応用を考えるのだな!」と感激したことを覚えています。

天才芸術家は『テルマエ』主人公と同じ?

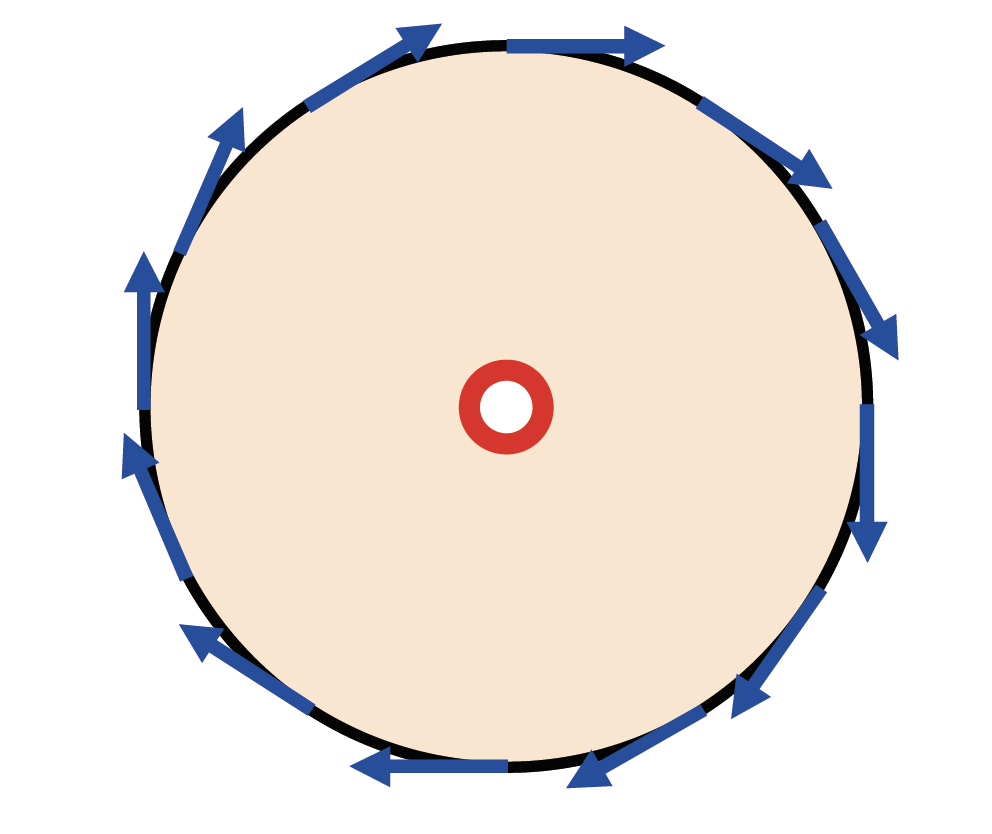

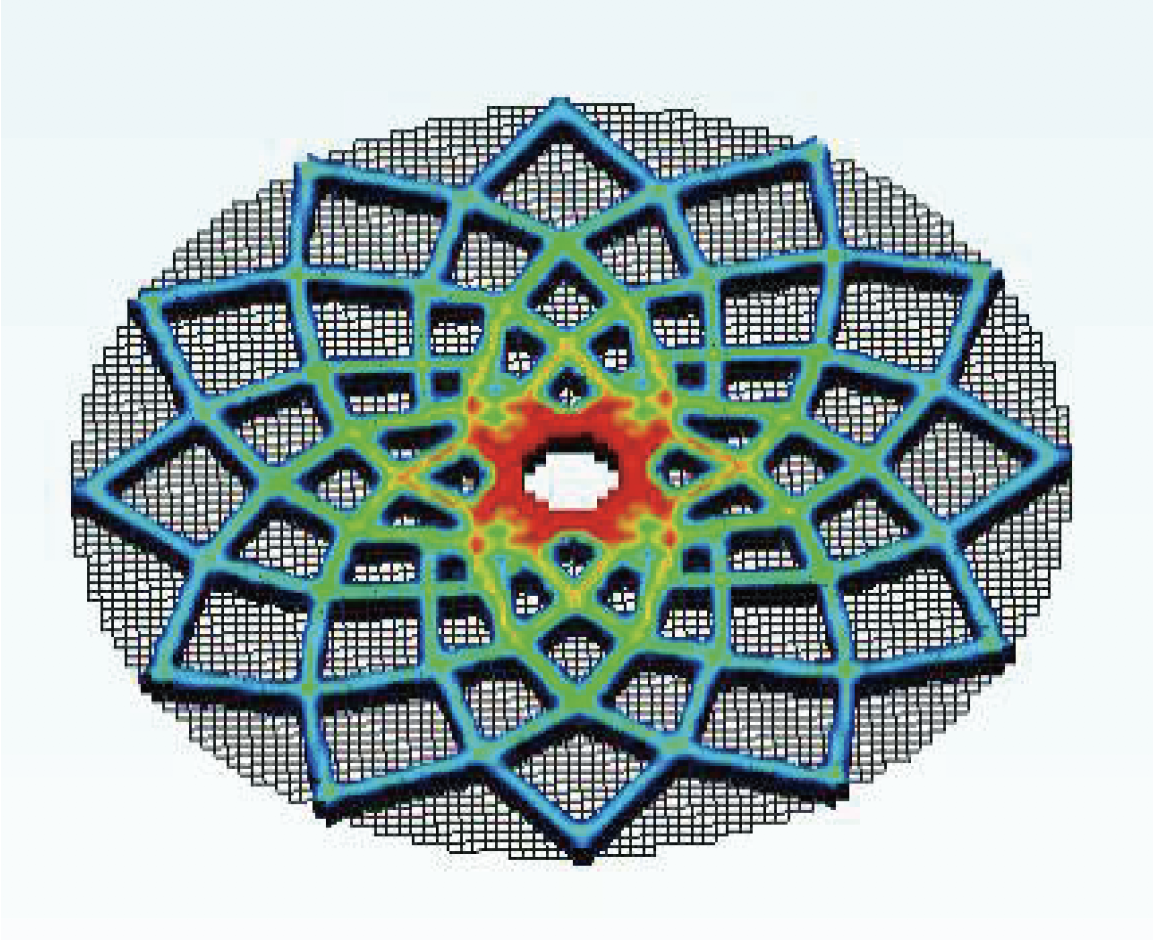

「天才は人の見えないものが見える」とよく言われます。ローマの観光名所カンピドリオ広場にミケランジェロが描いた直径10mを超える大きな円の絵があることをご存知でしょうか。私はトポロジー最適化でこの形が作れないか、考えてみました。

このベージュ色の円盤の赤い中心部を固定して、時計と同じように12時1時2時3時…と円周方向に捻って回転させる力をかけます。同時にこの力に抵抗できるようにベージュ色の部分の質量を3/4除き、残りの1/4の材料で形を作るようにPCで1分位計算すると、まさにミケランジェロが描いた絵と同じ形が出てきます。しかも辺の本数までぴったり同じ。これには驚きました。やはり天才ミケランジェロ、見ているものが違います。

この話をある社外のセミナーで対談相手にお話ししたところ、「石井さん、それは違います」と言われました。僕が映画好きであることから日本映画の『テルマエ・ロマエ』を引き合いに出して、「ミケランジェロはこの映画の主人公と同じです。きっと現代に来てOPTISHAPEの計算画像を見て、自分の時代に帰ってからこれを作ったのですよ」と、そう言って譲らないんです(笑)。お世辞だとしても嬉しかったです。

その方は、八重洲ブックセンターのビジネス書売上No.1に輝いたこともあり、さすがに発想は面白いなと感心して、「そのアイデア、僕も使っていいですか?」と聞いてお許しが出たので、今日ここでお話ししています。

数学の知見に裏打ちされた形状最適化

OPTISHAPEの特徴であるトポロジー最適化に加え、もう一つの特徴である形状最適化についてもお話しします。形状とトポロジーの違いを簡単に説明すると、空いている穴の数(表面の数)が異なる構造物はトポロジーが異なります。サイコロみたいな立方体も直方体も球もトポロジー形状は同じですが、それらがドーナツみたいな形になったときにはじめてトポロジーが変化したことになります。

ところがトポロジーを変化させなくても、従来の製造方法が利用でき、表面形状だけを変化させて望む性能を得ようという研究を長年やってこられた方が、現在名古屋大学教授の畔上秀幸先生です。畔上先生は30年間に渡って形状最適化を研究しながら、1つ1つの疑問がきちんと数学的に正しいか、収束するかをひたすら検証してこられました。

OPTISHAPEはその知見を使わせていただいているのですが、“数学的にきちんと裏付けされているものは破綻しない”ところがすごい。この技術で我々は世界の強豪相手に共通のベンチマークテストで戦っても負けたことがありません。必ずOPTISHAPEが勝ちます。それぐらいすごいのです。

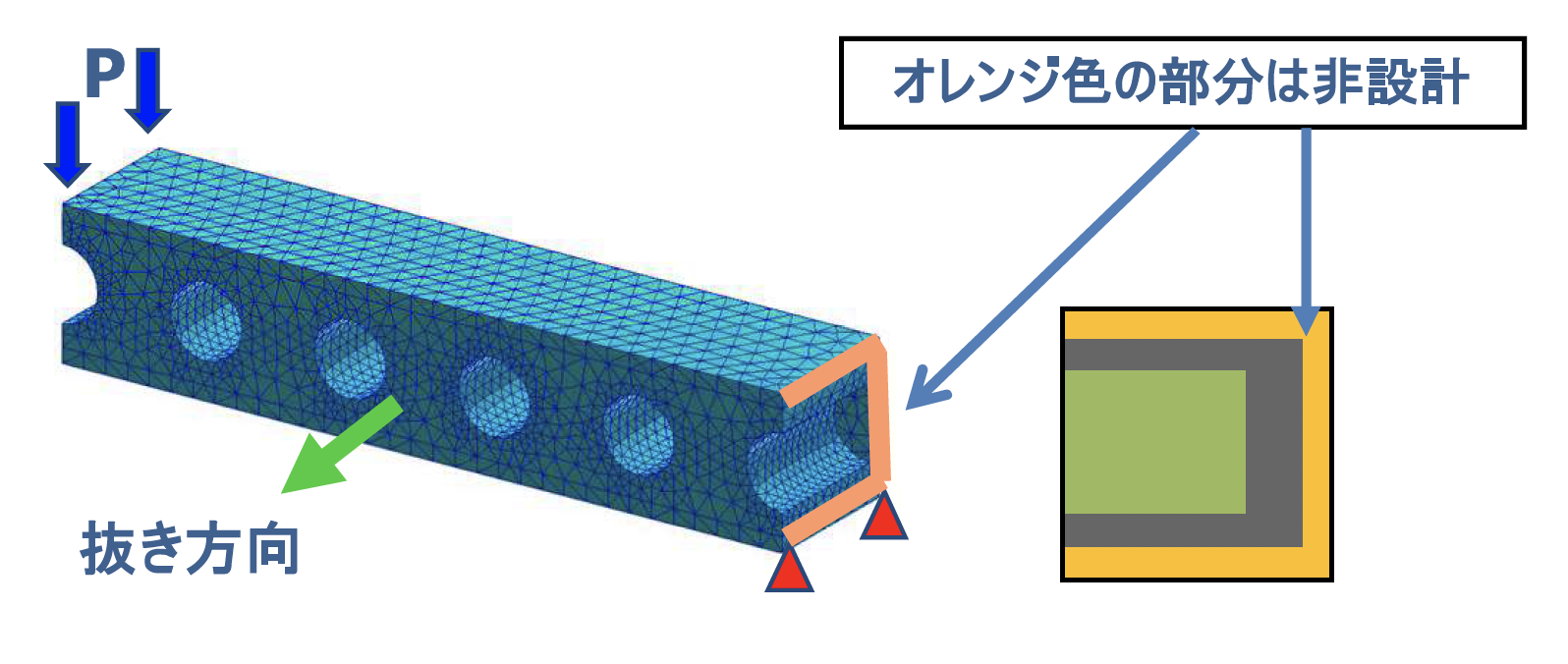

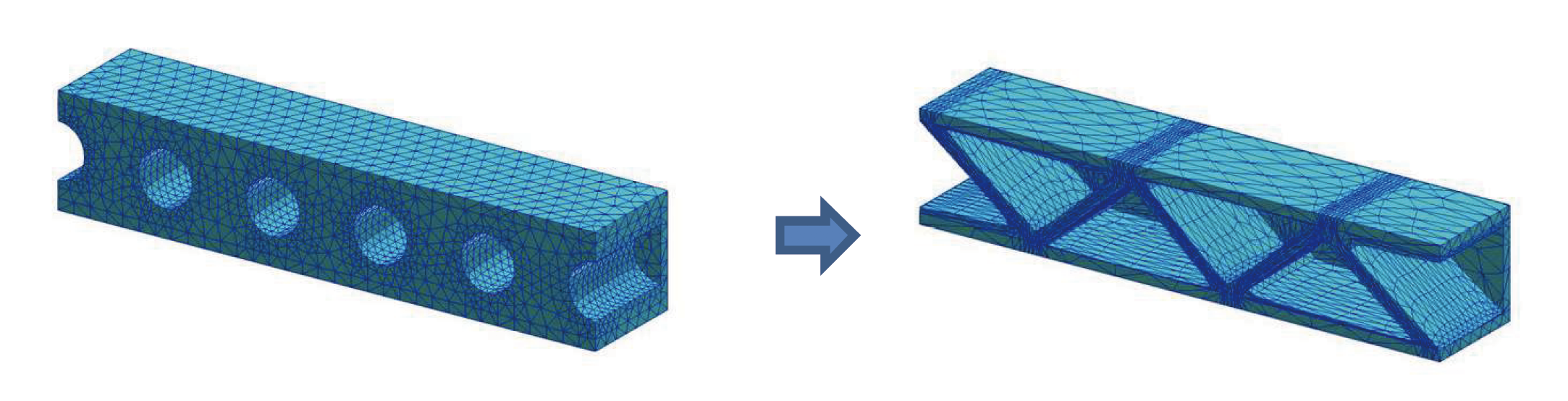

材料力学の教科書に、棒の両端をクランプし中央に荷重を加える「三点曲げ問題」があります。これを少し難しくして、丸い穴が空いている構造とし、これを形状最適化の視点で解こうとすると、対称条件を利用して、棒の半分だけモデルを作り、さらに棒には円筒の穴が空いており、断面のオレンジ色の部分(下図参照)は削ってはいけないとします。他の部分は削ってもいい。ここからいろいろな条件を与えて最適化していくと、結果的に棒の丸い穴が、なんとトラス形状の三角形になるという結果が得られます。

通常、海外のソフトウェアはここまでたどり着けませんが、そこも工夫次第で解決策を導き出せるというOPTISHAPEの性能を示す一例になっています。

ブレーキキャリパーの振動制御例

工学の分野に「固有振動を制御する」という長年の研究課題があります。これは大変な課題で、指標になる固有振動数がいくつもあり、一つの固有振動数を上げる形状に変更すると、他の振動数の数値が下がったりして、まるでモグラ叩き。思い通りにいきません。3つ制御するだけでも実に大変なことだと言われています。

という前提を踏まえて、これから紹介する例は「14個の固有振動数を全てある値にしてほしい」というクレイジーなリクエストに応えた事例です(笑)。

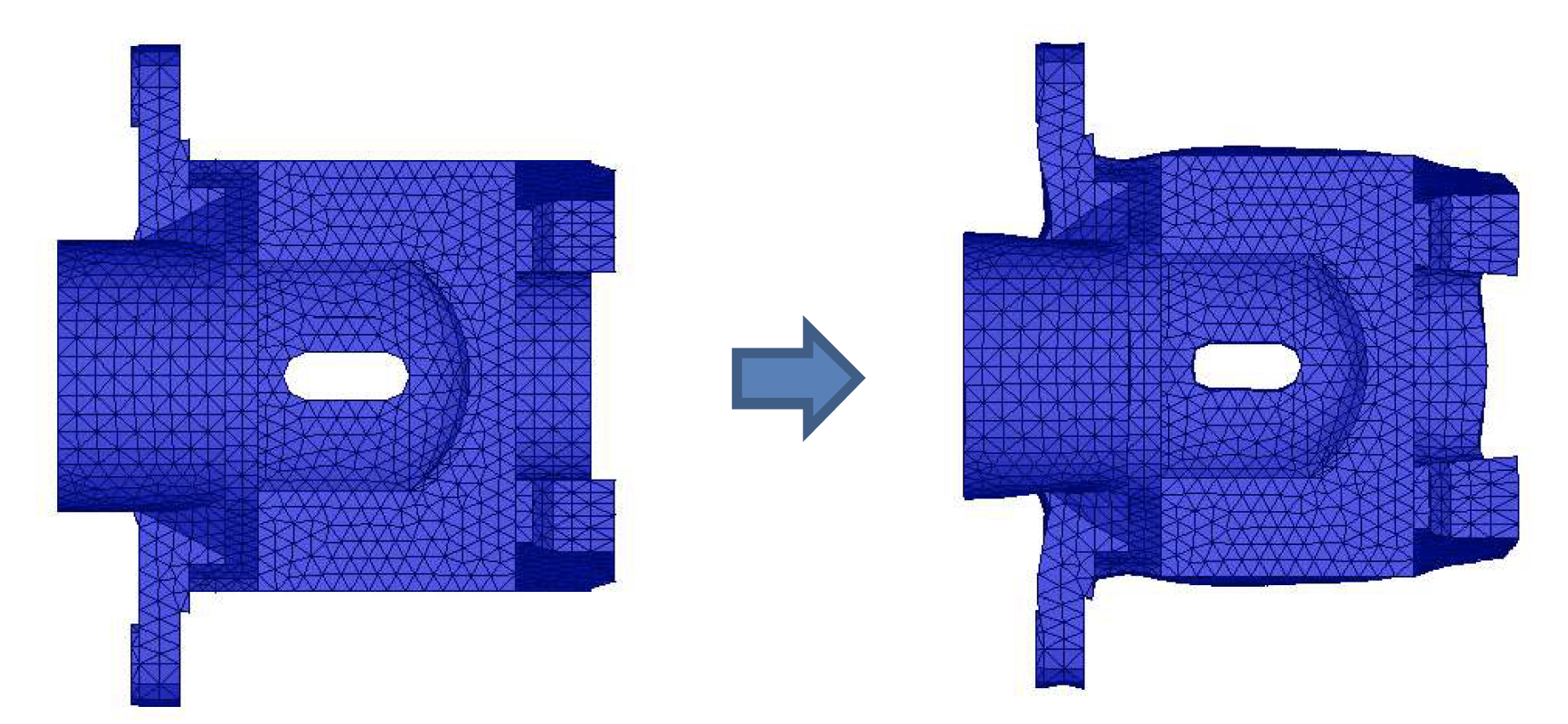

ある自動車会社が「自社のブレーキキャリパーが超高速からフルブレーキングをすると、すごく嫌な音がする」と相談に来ました。ある海外の車で同じ条件で試したらほとんど音がせず、設計者の方が真っ先に考えた要因がブレーキキャリパーなのではないか、ということでした。

ブレーキキャリパーには油圧のピストンや大きなブレーキディスクがあり、ディスクの円盤やその周辺、丸いピストンが往復する部分の形状はいじれない。でも外側はいじっていいという、まさに形状最適化の問題に当てはまります。

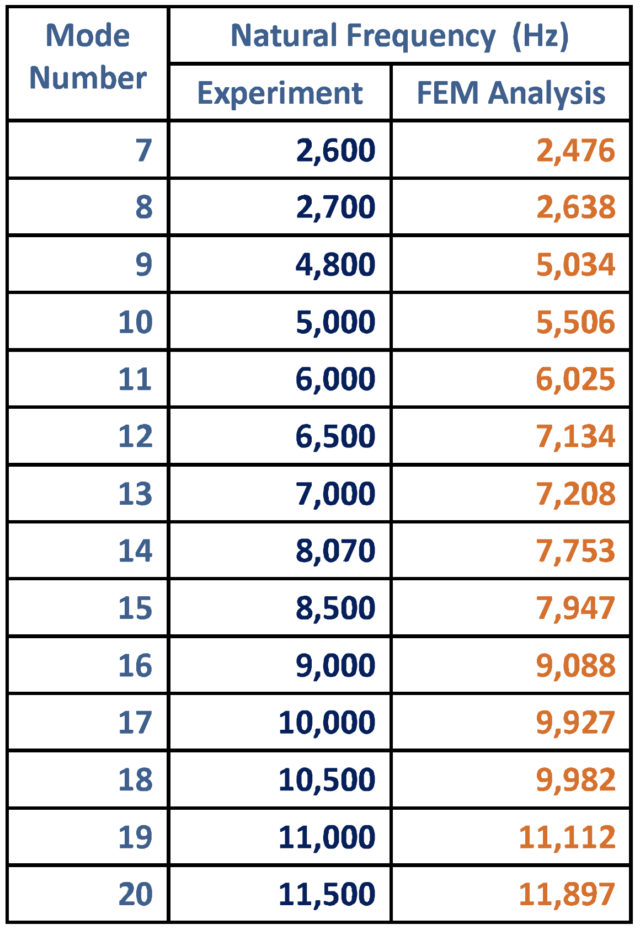

我々が取り組んだことはまず、嫌な音がしなかった海外の車のブレーキキャリパーの加振実験から得られた固有振動数をいただき(表左側のexperiment)、それから、キャリパーの有限要素モデルを作り、固有振動数を計算し(表右側のFEM Analysis)、計測値に近づけることを目標としました。

結果は、“どんなに熟練した技術者でも3つ以上の振動制御は絶対無理だ”と言われているところを、14個もある固有振動数全てを、計測値との差がわずか0.1%未満にまでもっていけました。15回グルグルっと回しただけで、その間形状が変わりながら最後には数値がピシッと合ってしまったんです。

こういうことをいとも簡単に成し遂げられるのは、OPTISHAPEが力学現象を定式化したモデルの固有値と、感度と呼ばれる「設計変数の微小な変化に対する、評価関数の変化の割合」も含めてきちんと計算しているからです。高性能のPCを用いて、わずか17分でこんな結果を出すことができる。これは理屈がきちんとしているからこそできる話です。

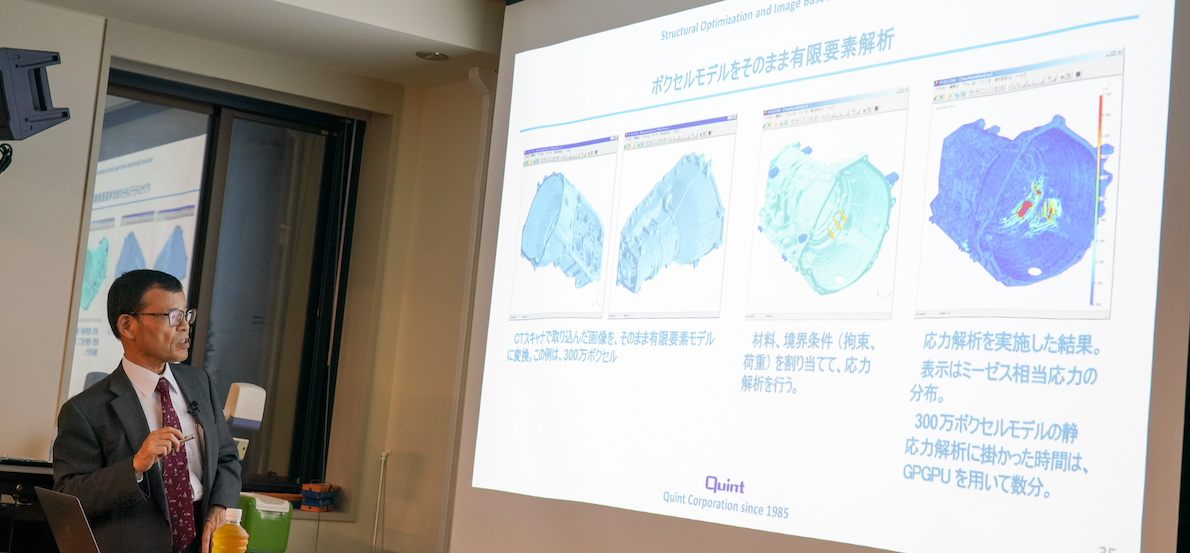

VOXEL(ボクセル)モデルの開発

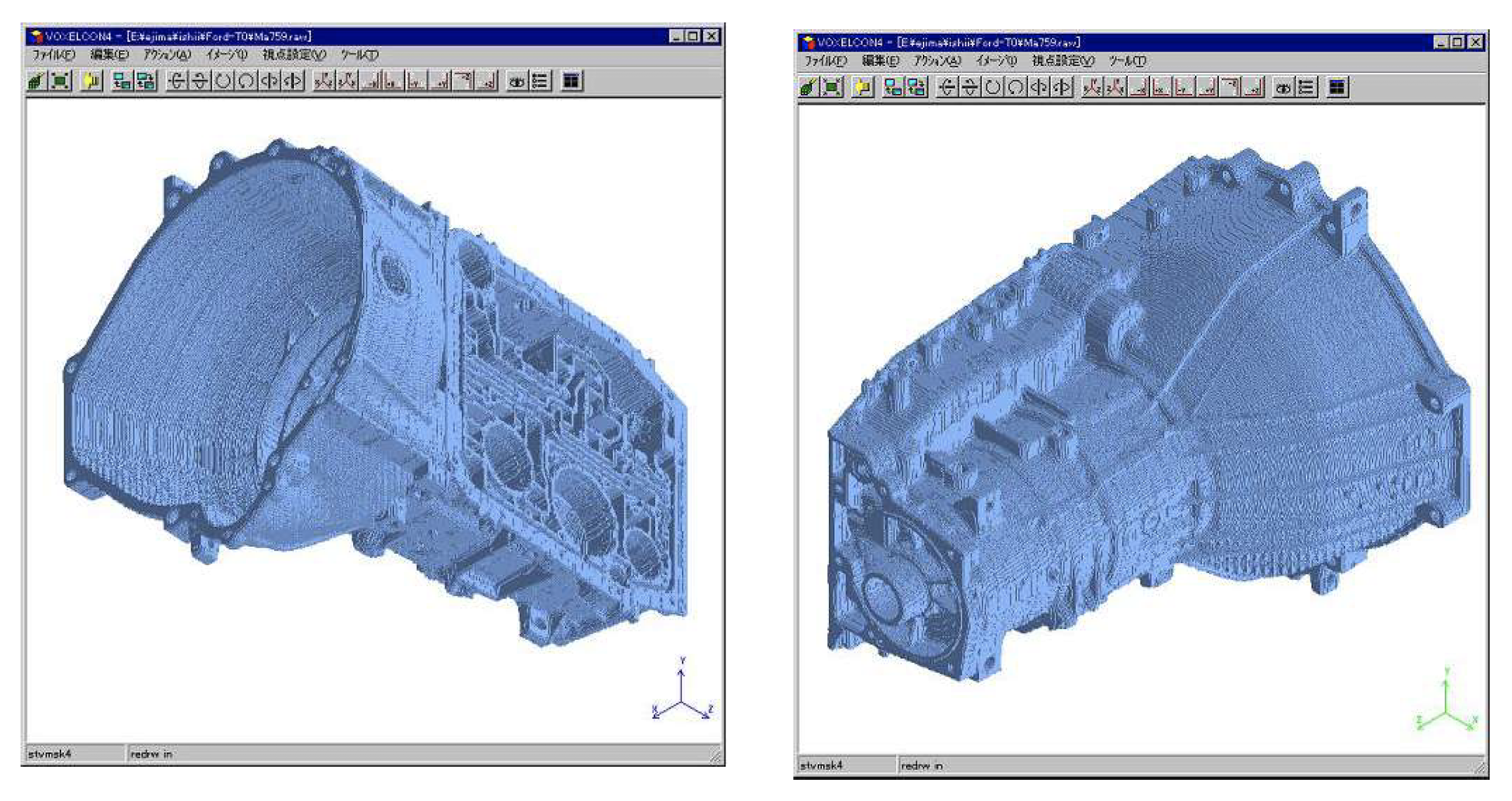

我々はベンチャーですから、“人がやらないこと”を主にやってきました。イメージベースモデリング・構造解析・計測ソフトウェアVOXELCON(ボクセルコン)の開発もその一つです。VOXELとは立方体のことで、ボリュームとピクセル(画素)を合わせた造語です。

開発のきっかけはこうです。アメリカのビッグスリーの一社のピックアップトラックに使われているトランスミッションケースは、実は日本の広島の会社が設計していました。そのトランスミッションケースを切削加工するときに亀裂が入り、「設計ミスではないか?」とクレームが入り、同社のCAEグループに解析依頼が来たそうです。

その原因追及のためにそれを解析しようと手を尽くし、結局FEMモデルを作るだけで巨大な工数が掛かることがわかり、担当者は途方にくれました。そこで前述したミシガン大学の菊池昇先生が「CTでX線を当てたらトランスミッションケースの中の複雑な部分も画像が出るんじゃない?」と提唱し、産業用CTで取り込んだ画像のドットをキュービック(立方体)のボクセルモデルにして、新たにミシガン大で開発したVOXEL有限要素法のプログラムを使い、荷重をかけて応力を計算したところ、別に変なものは出てこなかったのです。

その結果をクライアントにフィードバックして製造部門で検証したら、何の事はない、製造現場でマニュアル通りに加工していなかったケアレスミスであることがわかりました。

そこからです、これは面白いから製品化しようと。しかもただ製品化するだけでは面白くないのでマルチスケール解析をHomogenization method(均質化法)で行うソフトウェアも一緒にVOXELCONの中に入れました。今、このソフトに関していろいろなところから問い合わせや注文が来ています。最初の開発からほぼ四半世紀が経っていますが。(笑)

ベンチャー企業が斬新な商品を作ると25年や30年は我慢しないとなかなか花が開きませんが、花が開き始めると必ず世界の巨大な資本が参入してくるので結構大変なんですよ(笑)。

「くいんとセミナー」で最先端技術を紹介

我々の会社は今18人ですが、スタート当初は5人しかいませんでした。こんな小さい会社を世界に知ってもらうには、「よそではやってないことをやらなければ」と考えました。

そこで我々が注目したのは、CAEの中に内在する様々な側面――ベースになっている基礎理論やそれを構成する方程式に関する理解をユーザーが深めること。ソフトウェアを使っていると、そういうことは意外とブラックボックスのまま使いがちですが、実はとっても大事なことなのです。そこに注目して、世界の当該分野をリードする研究者を招く独自のセミナーを毎年1回開催することにしました。

これはもう、当初は全部会社の持ち出しですが、続けているとだんだんお客様が増えてきました。最近よく言われるのは「こういうセミナーって考えてみると、日本中どこの会社もやっていないよね」。それはそうです。Topology OptimizationやImage Based CAE、先ほどの畔上先生のH1 勾配法、それからHomogenization methodによるマルチスケール解析、これらの技術は全部、我々が国内でいち早く紹介してきたトピックス。「くいんとセミナー」で紹介した技術が15年後20年後に世界のスタンダードになっていきました。

Adaptive Mesh Refinementしかり、Topology Optimizationしかり、世界の強豪やベンチャーが次々と参入し、市場を奪い合っていく。Homogenization methodの市場も、もうすごく大きくなってしまいました。

このようにいつも先頭を切ってやってしまうとビジネス的には窮地に陥るのですが、私はそれで世界が広がったのならよしとしようと考えるようにしています。まあ、「正直、負け惜しみ」ですが、そういう風に考えています。

(3)につづく

石井 恵三 ISHII Keizo(株式会社くいんと 代表取締役)

1948 年、神奈川県横須賀市出身。1970 年、日本情報サービス株式会社(現、株式会社JSOL)に一期生として入社。1985 年 株式会社くいんと設立、代表取締役社長として現在に至る。 「位相最適化の応用に関する研究」で、2002 年、東京都立大学において博士(工学)の学位を取得。日本計算工学会より功績賞(2012)、技術賞(2015)を受賞。日本計算工学会フェロー(2013)。趣味はドライブと映画鑑賞。